Tractor beam can guide lightning

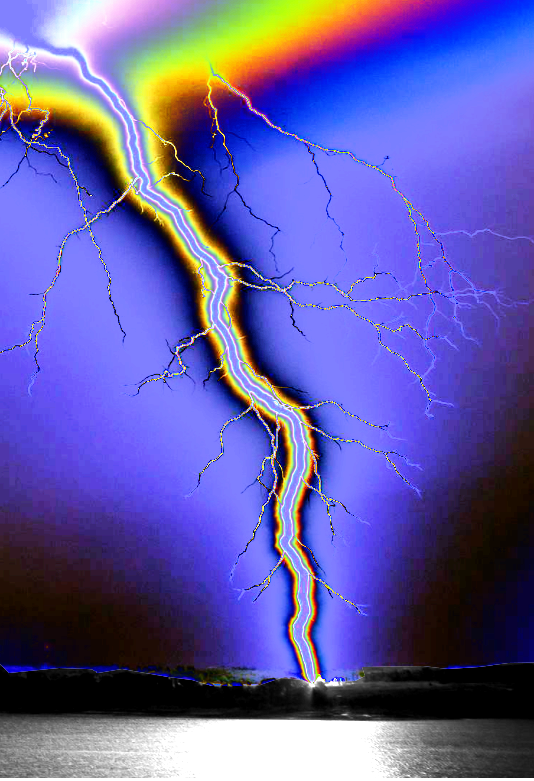

Australian engineers have developed a tractor beam to control where lightning strikes.

Australian engineers have developed a tractor beam to control where lightning strikes.

Many of Australia's devastating 2019-20 bushfires were caused by dry lightning strikes.

This may change in the future, with an international team of researchers, including scientists from The Australian National University (ANU) and UNSW Canberra, pioneering a laser tractor beam technology that has the potential to control the path and direction of lightning.

The team used a laser beam that mirrors the same process as lightning and creates a path that directs electrical discharges to specific targets.

The beam works by trapping and heating graphene microparticles in the ambient air. By heating the graphene microparticles trapped in the beam, the team was able to create the necessary conditions for electric breakdown and transmission along the laser's path.

In their latest tests, they were able to achieve the feat using a laser intensity a thousand times less than that in any previous attempts, meaning any potential technology to control lightning could be much cheaper, safer and more precise.

The breakthrough has important applications for reducing bushfire risk as the tractor beam can be guided over long distances and allows for precision control of the lightning's discharge.

“The experiment simulated similar atmospheric conditions to those found in real lightning,” said researcher Dr Vladlen Shvedov, from the ANU Research School of Physics.

“We can imagine a future where this technology may induce electrical discharge from passing lightning, helping to guide it to safe targets and reduce the risk of catastrophic fires.”

Professor Andrey Miroshnichenko, from UNSW Canberra, said it could be a very powerful tool.

“We have an invisible thread, a pen with which we can write light and control the electrical discharge to within about one tenth the width of a human hair,” Professor Miroshnichenko said.

The discovery also has potential for the micro-scale control of electrical discharge in medicine and manufacturing applications.

“The medical applications include optical scalpels for the removal of hard cancerous tissue to non-invasive surgery techniques,” Professor Miroshnichenko said.

“We are really at the start of learning what this completely new technology might mean.”

Print

Print